Microgreens farming is gaining remarkable traction in South Africa’s agricultural market. These are tiny, edible young plants (harvested just 7 to 21 days after germination) that pack intense flavor and nutrition into a small package. In fact, a handful of broccoli microgreens can contain as many nutrients as an entire head of broccoli.

Chefs and foodies love microgreens for their vibrant colors and potent taste, likening their flavor impact to “magical chewing gum” from Willy Wonka’s factory.

Health experts praise them for being nutrient-dense “superfoods” that may help reduce risks of obesity, diabetes, and heart disease.

It’s no wonder that what started as mere gourmet garnishes have evolved into real ingredients at trendy bistros and fine dining restaurants in Johannesburg and Cape Town.

For aspiring small-scale farmers and home growers, microgreens farming presents a unique opportunity.

Microgreens require very little space and can even be grown indoors under lights or in controlled environments like simple greenhouses.

A tiny area can yield a surprisingly large harvest, as one South African farming magazine put it, microgreens are “a tiny crop with big returns”.

With consumer demand on the rise, South Africa’s microgreens market is expected to nearly double in value over the next decade (from about USD 44 million in 2023 to roughly USD 92 million by 2030).

This growth is driven by urban agriculture trends, health-conscious diets, and the premium prices microgreens fetch at market.

According to recent research, South Africa’s microgreens sector could reach around R400 million in revenue by 2030, growing about 11% per year.

Microgreens farming aligns perfectly with the needs of small home-based entrepreneurs, it has a low startup cost, quick production cycle, and strong demand among high-end buyers.

In this comprehensive guide, we’ll explore what microgreens are and why they are so popular. We will delve into how you can start a microgreens farming business at home in South Africa, including the equipment, growing process, and potential income.

We’ll also discuss the market outlook, target customers, and pricing in the South African context.

Importantly, we’ll cover the legal and regulatory steps (like food safety certifications) you need to know to run a microgreens business from home.

By the end, you’ll understand why microgreens farming is an ideal avenue for small-scale farmers and how you can cultivate a thriving microgreens venture of your own.

What are Microgreens? (And Why They’re Booming)

Why Microgreens Farming in South Africa?

Opportunities and Benefits for Small-Scale Microgreen Growers

Challenges to Consider in the Microgreens Business

How to Start a Microgreens Farming Business at Home

Costs and Income Potential of Microgreens Farming

Marketing and Selling Your Microgreens

Legal and Regulatory Requirements in South Africa

Microgreens are the tender young seedlings of vegetables and herbs, harvested at an early stage, usually when the plant has developed its first set of true leaves, around 5 cm tall. They are not the same as sprouts. With sprouts, you consume the seed and root after just a few days of germination (sprouts are grown in water, often in the dark).

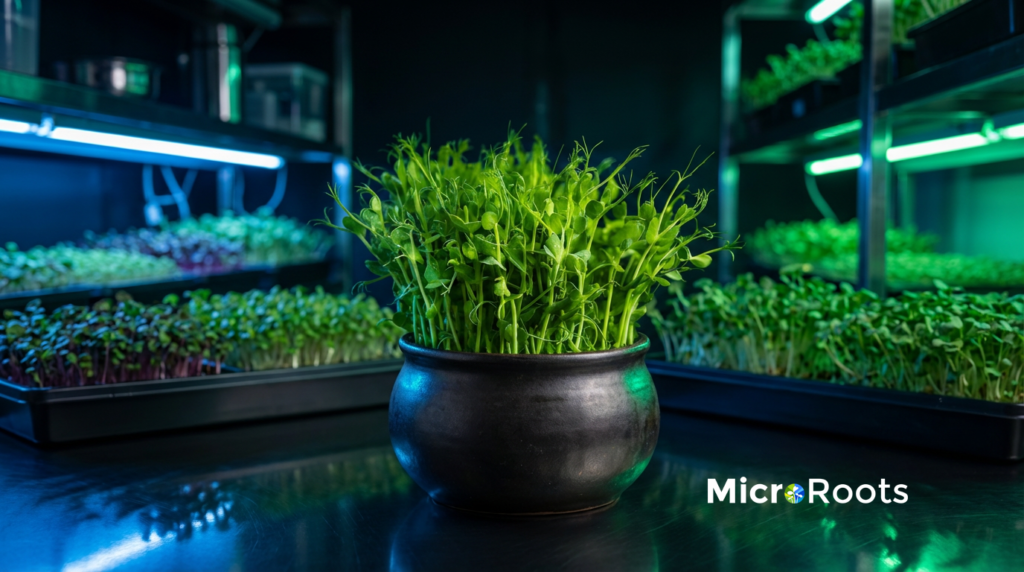

Microgreens, by contrast, are grown in soil or another growing medium under light, and you harvest only the stems and leaves, typically 7–14 days after germination. This distinction makes microgreens safer and more flavorful than sprouts, and gives them a unique texture. For example, mustard microgreens have a spicy Dijon kick, pea shoots taste like sweet peas, and beet microgreens carry an earthy beet flavor.

Microgreens can be grown from many different crop species. Popular varieties include radish, broccoli, kale, rocket (arugula), beetroot, basil, mustard, sunflower shoots, pea shoots, coriander, red cabbage, and more. Each variety brings its own color and taste, from the peppery bite of radish microgreens to the vibrant purple of amaranth or the mild crunch of sunflower shoots.

These mini–vegetables are nutritional powerhouses. Studies by South Africa’s Agricultural Research Council found microgreens offer substantial levels of vitamins, minerals, and proteins, along with antioxidants that help the body’s growth and maintenance. In many cases, microgreens contain significantly higher nutrient concentrations than their mature counterparts.

As urban gardener Lauren Roodt explains, because microgreens grow so rapidly, they concentrate nutrients: “They’re packed with beneficial enzymes, vitamins and minerals” – a handful can provide the nutrition of a whole mature vegetable. This means adding a small sprinkle of microgreens to a meal isn’t just a garnish; it’s a real nutritional boost.

Beyond nutrition, microgreens also address another important issue: food security. Because they grow quickly in minimal space, microgreens could help people who lack access to large land or fresh produce to grow some of their own nutrient-rich food.

Researchers suggest microgreens could play a role in fighting malnutrition. They’re not just for upscale restaurants, but also a way to provide affordable vitamins and minerals to communities. All these benefits have led to surging interest in microgreens among health-conscious consumers, dieticians, and chefs.

In South Africa, chefs have moved microgreens from being a mere “pretty touch” on the plate to being the hero of the dish in many cases. Dishes from sandwiches and salads to gourmet burgers are now loaded with fresh microgreens for flavor, texture, and visual appeal.

South Africa is experiencing a microgreens revolution of sorts, making it an exciting time to start a microgreens farming business. A few key trends explain why microgreens are taking off:

Consumer awareness of healthy, organic, and locally-grown foods is at an all-time high. Microgreens check all these boxes. They are pesticide-free (usually grown without any chemicals), harvested fresh, and known as nutrient-dense superfoods. As a result, demand is climbing steadily. Industry reports project South Africa’s microgreens market to grow significantly in coming years, with some estimates expecting the market to roughly double in value from 2023 to 2030. Even a smaller study pegged South Africa’s microgreens market at around $22 million (approx R330 million) by 2031. The trajectory is clear: more people are buying microgreens, whether for gourmet cooking or healthy home meals.

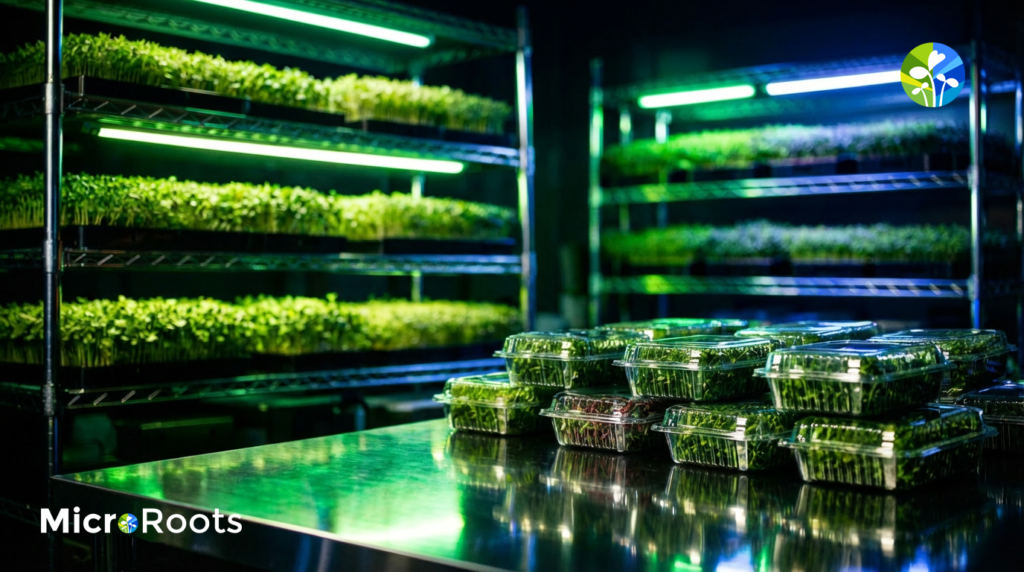

Unlike many crops, microgreens are perfectly suited for urban and suburban cultivation. They can be grown indoors or in greenhouses year-round, so producers can operate from a city apartment, a garage, or a small backyard. In South Africa, most microgreens production happens in controlled environments like greenhouse tunnels or vertical farming racks, which means consistent supply even during winter or harsh weather.

This gives small growers a big advantage, you don’t need a farm out in the countryside. For example, one Johannesburg-based producer, Urban Microgreens, grows 16 varieties of microgreens on a plot smaller than the average suburban backyard, using vertical indoor racks. Despite the tiny footprint, they harvest about 2,000 punnets of microgreens per week and supply over 300 shops, hotels, and restaurants. This illustrates how microgreens farming enables intensive production in a small space, ideal for South Africa’s urban farmers.

Microgreens are a high-value niche product. They’re considered a gourmet ingredient, and top restaurants, boutique grocers, and health food stores are willing to pay premium prices for them. In South Africa, a small punnet (around 30–50 g) of microgreens can retail for roughly R30–R50 depending on the variety and market. Even wholesale to restaurants often runs ~R40 for 40 g (R1,000 per kg).

These prices are far higher per kilogram than most traditional vegetables. This means a microgreens farming business can earn good revenue from a small output, as long as there is market demand.

One couple in Mpumalanga started growing microgreens as a hobby and soon found local demand; by 2020 they were supplying about 30 kg of microgreens a month to restaurants and farm stalls, calling it a stable business and a “decent income”. That 30 kg/month was achieved with just a 5 m × 2.5 m simple greenhouse in their backyard. Such success stories are becoming more common, especially around major cities.

Avoid common beginner mistakes and start your microgreens journey with clarity and confidence.

South African consumers, like those globally, are increasingly interested in healthy eating and “functional foods.” Microgreens, given their vitamin and antioxidant content, align perfectly with this trend.

They’re gluten-free, vegan, low-calorie, but packed with nutrients, appealing to a range of diet preferences. Microgreens are often branded as a local superfood. Producers can market their microgreens not just for flavor, but for the health angle (e.g. broccoli microgreens for their sulforaphane content that may fight bacteria and cancer, or radish microgreens for vitamin E, etc.).

This health halo helps drive retail sales. As one producer noted, once people learn “they have 40% more nutrition than vegetables” on average and various health benefits, demand will really grow. Part of your job as a microgreen farmer will be educating customers on these benefits, which in turn boosts your sales.

South Africa’s variable climate (hot summers, occasional frost in winters, etc.) can be a challenge for conventional farming. But microgreens farming is largely climate-proof since it’s done in controlled environments. You can manage light, temperature, and water easily. The ideal temperature range for most microgreens is 18–24 °C with moderate humidity conditions that are easy to maintain indoors or with simple insulation and shade cloths.

Rain, hail, or drought won’t directly affect an indoor microgreen crop, making it a more predictable venture than outdoor farming in many cases. However, one local challenge is loadshedding (power outages): if you rely on artificial lights or fans, you’ll need backup power solutions so your microgreens get consistent light and air circulation.

Many South African growers use LED grow lights on timers, which may require an inverter or generator backup during outages. Planning for this ensures year-round production despite electricity cuts.

The microgreens boom has led to supportive networks and resources. South Africa now has specialized suppliers (for seeds, trays, equipment) and even training courses for microgreen entrepreneurs.

Companies like MicroThumbs (Johannesburg) and Cape Microgreens (Cape Town) have emerged as leaders, demonstrating the viability of the business by supplying major clients and even franchising microgreen growing systems.

Their success paves the way for newcomers and has created a knowledge-sharing community. You’ll find active social media groups where local growers discuss pricing, techniques, and market leads. All of this makes it easier for you to jump into microgreens farming with confidence that a support system exists.

In summary, South Africa offers fertile ground (quite literally) for a microgreens enterprise. Growing consumer demand, urban farming suitability, high-profit margins, and the ability to start small with low risk are strong reasons to consider microgreens farming as a home business. Of course, like any business, it comes with challenges and competition, which we will discuss, but the opportunities are compelling.

For a home-based or small-scale farmer, the benefits of microgreens farming are numerous. Here are some of the major opportunities this niche offers:

Microgreens are a premium product. Gourmet restaurants, upscale grocers, and health food stores are willing to pay top dollar for fresh, locally grown microgreens. This means you can earn more revenue per kilogram of produce than almost any other vegetable crop. A small batch of microgreens can sell for a high price, giving you a healthy profit margin if managed well.

Microgreens require only a small land footprint. You can grow an abundance of trays vertically on shelves or racks. This makes microgreens farming ideal for urban and suburban settings where land is limited. Whether it’s a spare room, a garage, a balcony, or a tiny greenhouse in the yard, you don’t need much area to start. (As noted, even a yard < 50 m² can support a commercial microgreen operation with vertical growing techniques.)

The turnaround time for microgreens is incredibly fast. Most varieties are ready to harvest in one to three weeks. These rapid growth cycles allow for consistent, continuous harvests and income. You can sow and harvest every week, avoiding the long wait (and risk) of traditional crops that take months. Quick cycles also mean if you make a mistake, you can correct it in the next cycle without huge losses.

Because you can grow microgreens indoors or in protected environments, you aren’t limited to a single planting season. Year-round production is feasible, which means cash flow throughout the year. You can supply customers even in winter when other local produce is scarce, giving you a market advantage.

Entering microgreens farming doesn’t require heavy machinery or expensive land. You can begin with some shelves or tables, inexpensive planting trays, growing medium, and quality seeds. Many growers start with just a few thousand rand of investment for basic supplies. There are even starter kits available for a few hundred rand that include trays, a small amount of medium, and seeds – useful for initial experiments. Compared to most agricultural businesses, microgreens have a low barrier to entry financially.

As discussed, microgreens practically market themselves with their health benefits. Being able to promote your product as local, fresh, and packed with nutrients is a strong selling point. This aligns with global wellness trends and gives you an edge in marketing. People are often willing to pay more for foods they perceive as contributing to their health.

Microgreens farming can start as a part-time side business and later scale up if demand grows. You have flexibility to grow the operation gradually. Since the infrastructure is modular (more trays, more shelves can be added), you can expand production without needing new land, perfect for someone beginning at home. It’s also labor-flexible; many small microgreen farms are run by one or two people, often as a family business.

These opportunities make microgreens farming very attractive for small-scale growers. It’s important to leverage each benefit: for instance, emphasize quality to maintain those premium prices, and use your small scale to your advantage by offering personalized service or specialty varieties that big farms can’t easily do.

South African microgreen startups like Bumblebee Organics in Mpumalanga exemplify this potential: they turned a hobby into a business supplying local restaurants within months, and they run it with just the husband-wife team and one assistant.

In their case, only half of their modest greenhouse capacity was enough to generate steady income, with room to double output when they decide to expand. Stories like this highlight that with microgreens, small can be mighty.

While the prospects are bright, a savvy entrepreneur should also be aware of the challenges in microgreens farming, especially in the South African context. Here are some key challenges and how to prepare for them:

Outside of foodie circles and high-end restaurants, many consumers still don’t know what microgreens are. There’s often confusion between microgreens, “microherbs,” and sprouts. As one small grower lamented, customers sometimes don’t understand the product and its value.

Part of your job will be educating your market, at farmers’ markets you might need to offer samples or recipe ideas, and for retail, include information on your packaging about how to use microgreens. The good news is awareness is growing, but you should be ready to evangelize the benefits of microgreens to new customers. Building consumer knowledge will expand your sales in the long run.

To consistently grow high-quality microgreens, you need good seeds, growing medium, trays, and possibly artificial lighting and climate control. These inputs can be relatively costly on a per-unit basis. For example, specialized microgreen seeds often come in small quantities and can be expensive to ship if not available locally.

If you invest in LED grow lights and backup power to mitigate load-shedding, that’s another upfront cost. Labor is also a factor, while microgreens are not labor-intensive compared to field farming, they do require daily attention (watering, monitoring).

All these expenses mean you must price your product to cover costs and still profit. Scaling up production can improve efficiency (buying seeds in bulk, etc.), but until you reach that point, managing costs is crucial. Start small and optimize your growing process to minimize waste (e.g., avoid overseeding which can lead to mold and loss of a whole tray).

Microgreens are delicate and have a short shelf life. Once harvested, they wilt relatively quickly if not kept cold. Freshness is absolutely critical. Chefs and consumers want crisp, vibrant microgreens. This means you’ll need a solid post-harvest plan: ideally harvesting to order, quickly cooling the produce, and delivering fast.

Many growers harvest in the cool of late afternoon or early morning and refrigerate the microgreens immediately, delivering them within 24 hours. You may need a cooler box or refrigeration for transport. If you are delivering to restaurants across town, factor in that time and cost.

Localizing your market helps; many microgreen businesses keep distribution within their city or region to maintain quality. Additionally, packaging must preserve the product, typically microgreens are sold in ventilated plastic punnets or clamshells that allow some air but also retain moisture.

Mastering the supply chain (harvest, pack, deliver in short order) is key to your reputation. Remember that unsold product is essentially lost profit, so try to match production to demand closely, or have preservation plans (some farmers turn extras into pestos or juices, but primarily you want to sell fresh). Overall, ensure you can meet the challenge of getting the microgreens to customers in peak condition.

As microgreens popularity grows, more players are entering the market. In major metros like Johannesburg, Pretoria, Cape Town, and Durban, you might find several microgreen suppliers vying for the same restaurant clients or store shelf space. Competition isn’t a deal-breaker, it’s a sign of a healthy market, but you’ll need to differentiate yourself.

This could be by offering unique varieties (some growers specialize in exotic or colorful microgreens like red amaranth, purple kohlrabi, or edible flowers to stand out), superior quality, organic certification, or exceptional service (e.g., custom growing to a chef’s needs). Maintaining consistent quality and food safety will set you apart, as will reliability in supply.

Since microgreens are still a niche, the industry in South Africa isn’t yet saturated, but it is concentrated around high-demand areas. Be prepared to carve out your niche and possibly collaborate rather than only compete. For example, some growers focus on retail packs while others focus on restaurant bulk supply.

Networking with fellow growers can even lead to sharing excess demand or tips. Still, any new entrant should study the local market: who is already selling microgreens and what can you do differently or better? As more entrants come, the bar for quality and uniqueness rises, so plan on staying agile and innovative.

While indoor farming avoids weather issues, it introduces dependency on technology. Power outages (loadshedding) have been mentioned but also consider water access and quality. Microgreens need clean, safe water (if your municipal water is chlorinated heavily or if you use borehole water, you might need to filter it to avoid any contaminants on your greens).

Pest and disease pressure is generally low for microgreens (since the cycle is short and you don’t use soil that harbors pests), but mold can be a common issue if airflow is poor or seeding density is too high. You will need to manage your growing environment carefully: maintain good ventilation (fans or natural airflow) to prevent fungal growth, and sanitize trays between plantings to keep disease at bay.

In South Africa’s climate, extremely high summer temperatures can also be a problem if your grow area isn’t cooled. Microgreens may suffer or dry out if above 30 °C for long. So, ensure your grow space can be kept in the ideal range (shading a greenhouse, using an evaporative cooler, or simply growing in a cool room in the house).

Humidity above ~80% can encourage mold, so dehumidifiers or ventilation might be needed in some setups. These are technical challenges that are solvable with attention and basic equipment, but they are part of the learning curve.

Despite these challenges, many South African small-scale growers are successfully running microgreens businesses. The key is to be aware and proactive: educate your consumers, control your costs, perfect your harvest/delivery routine, differentiate your brand, and manage your grow environment meticulously.

In the next sections, we will give you practical guidance on starting your microgreens farm, including tips to navigate some of these challenges.

Getting started with microgreens farming at home is relatively straightforward. Here’s a step-by-step look at what you need and how to begin growing your first microgreen crops. The focus here is on a small-scale setup ideal for beginners.

You don’t need a farm or big greenhouse, a corner of a room, a garage, or a small patio can work. The space should be sheltered from extreme temperatures and pests. Many home growers use simple shelving units to stack multiple trays vertically, maximizing space. Ensure you have access to electricity (if using grow lights) and water.

If outdoors, you might build a mini greenhouse or tunnel to protect from rain and temperature swings. For instance, a 5 m × 2.5 m greenhouse made of plastic sheeting was enough for one South African couple to produce 30 kg/month of microgreens.

Indoors vs. outdoors: Outdoors (or in a greenhouse) you get free sunlight but must manage heat and cold. Indoors, you’ll need artificial lights but can control climate easily. Choose what suits your environment and budget. Many start indoors on a rack with lights, whereas some in temperate areas grow on a porch with natural light.

Microgreens need ample light to grow tender but not lanky. If using sunlight, aim for a spot with at least 4–6 hours of direct or bright light per day. If growing inside or during winter, invest in full-spectrum fluorescent or LED grow lights.

These should be positioned above the trays. Microgreens generally require 12–16 hours of light per day for optimal growth. Lights that are too weak or too far will cause thin, pale sprouts; too close and you risk overheating them. A common approach is to hang adjustable LED strip lights or bulbs on each shelf tier. Remember to plan for backup during load-shedding if indoor, even a few hours without light each day can affect growth.

Keep the growing area in the optimal temperature range (approximately 18–24 °C). Most homes are in this range, but in winter you might need a small heater in a garage setup, and in summer ensure some cooling or airflow.

Good air circulation is important to prevent mold, a small fan blowing gently across the trays can make a big difference. If using a covered greenhouse or cabinet, open it up daily for fresh air exchange. Maintain cleanliness; this is food you’re growing, so keep the area free of pests and dirt.

Healthy microgreens sprouting in a tray under controlled conditions. They require clean growing media, proper light, and good airflow to thrive.

One advantage of microgreens farming is the short list of equipment needed. Here are the basics:

Shallow trays about 3–5 cm deep work best. Standard 25×50 cm nursery trays are popular, but you can use any shallow, food-safe container (even recycled plastic food containers) as long as it has drainage holes. Make sure to create drainage holes if there are none, as standing water will cause rot. Also have a solid tray or plate underneath to catch excess water.

Microgreens can be grown on soil or soilless media. Options include peat moss or coco coir (very common, as it’s clean and renewable), potting soil mix, vermiculite, or specialized microgreen mats made of hemp or jute.

Each has pros and cons: soil/coir mixes often yield better flavor and don’t need added fertilizer since micros don’t require much beyond seed nutrients. Ensure any medium is sterile and free of contaminants. Many use a mix of coco coir and perlite for good water retention and aeration. You’ll fill trays with 2–3 cm of this medium as the “bed” for your seeds.

Use seeds specifically sold for microgreens or untreated bulk vegetable seeds. Regular garden seeds can work but avoid any that are treated with fungicides (often colored – those are for field planting, not direct consumption). Popular microgreen seeds in South Africa (like broccoli, radish, sunflower, pea, etc.) are available from specialty suppliers and even some garden stores.

Buying in bulk (1–5 kg bags) is more economical once you scale up. Note that seed quality matters, a bad batch can ruin your crop (e.g., carrying disease or poor germination). Start with reputable suppliers. You might also consider testing germination rates or trying small samples first.

You’ll need a gentle way to water your microgreens. A spray bottle or misting pump is great for the initial stage to avoid dislodging seeds. As they grow, a watering can with a fine rose can be used to water more thoroughly. Some growers water from the bottom by pouring water into the tray beneath so the roots soak it up, which reduces risk of harming the delicate stems.

In a small setup, simply be prepared to check moisture daily. Plan for around every other day watering, though this varies (in hot, dry weather you may water daily; in cooler conditions, less often). The key is to keep the medium moist but not waterlogged.

You’ll also benefit from having clean scissors or a sharp knife for harvesting, a scale for weighing produce (to package orders accurately), and food-safe containers or bags for packing the microgreens. Labels for your packages (with product name, weight, date, etc.) will be needed if selling.

Many micro farmers also keep some shelves or tables for working, fans or dehumidifiers if needed, and cleaning supplies (to sanitize trays between uses). But at heart, trays, medium, seeds, light, and water are your main “tools.”

Starting up with these items is quite affordable. Some entrepreneurs report initial setup costs as low as R9,000 for a basic shelf, lights, trays, and initial seeds. If you repurpose existing shelves or containers, costs can be even lower. The modular nature means you can begin with a handful of trays and scale up as you gain experience and market demand.

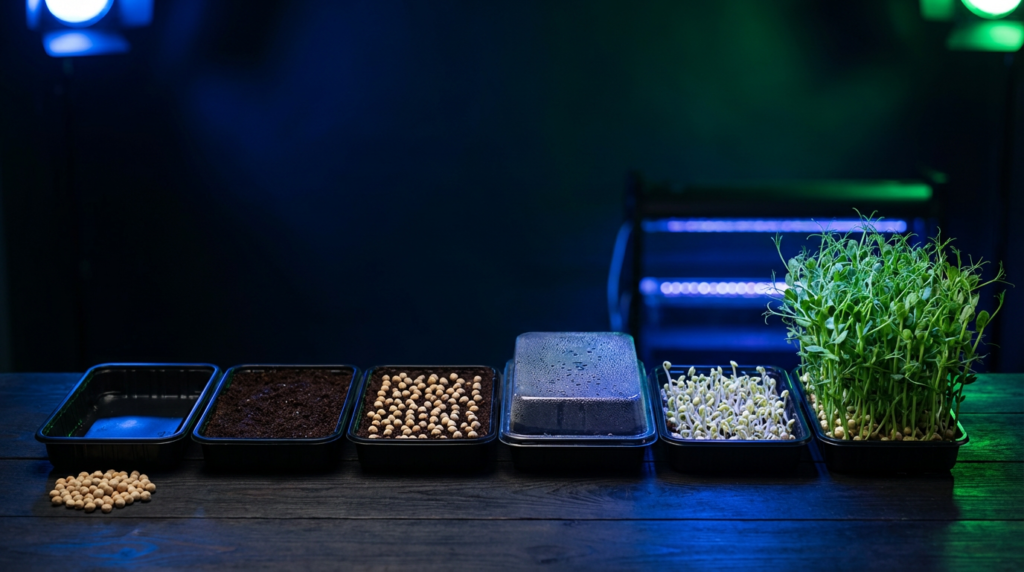

Now comes the fun part, growing your greens. Here’s a simplified overview of the growing process for a typical microgreen crop (like radish or broccoli):

It often helps to soak larger seeds (like pea, sunflower, beet) in water for a few hours (4–8 hours or overnight) before planting. This softens the seed coat and speeds up germination. Smaller seeds (broccoli, mustard, basil) usually don’t need pre-soaking.

Fill your tray with moistened growing medium about 2–3 cm deep. Level it and gently tamp it so it’s fairly even. Evenly scatter your seeds across the surface. Aim for a dense coverage but with minimal overlap. A rule of thumb for many microgreens is roughly 10 g of small seeds per tray of 30×30 cm, but this varies (e.g., 80 g per tray of radish, 150 g for sunflower, 200 g for pea in a larger 50×25 cm tray).

You’ll figure out the right seeding density with practice; too sparse yields less, too dense encourages mold. After seeding, you can lightly mist the seeds with water and optionally cover them with a thin layer of vermiculite or another sprinkle of medium. Not all growers do this, but some seeds prefer darkness to germinate.

For the first few days, it helps to keep seeds in the dark and humid. You can achieve this by stacking trays or covering the tray with a lid or another tray (this also presses the seeds slightly into the medium for good contact).

Many microgreen varieties germinate in about 2–4 days under these conditions. Check daily and mist with water if the medium is drying out. As soon as you see most seeds sprouting, it’s time to uncover and move to the light phase.

Once sprouts are up, expose them to light (sunlight or turn on your grow lights). They will start to turn green as chlorophyll develops. Ensure good air flow now, if you had trays stacked, unstack them so each has space. Continue watering as needed, microgreens like to be consistently moist.

Never let them dry out completely or they will quickly wilt. Conversely, avoid waterlogging; ensure drainage. Typically, watering once every 1–2 days with a gentle spray or bottom watering is sufficient. Monitor for any signs of mold, if spotted, improve airflow and remove infected portions carefully.

Most microgreens are best harvested at the first true leaf stage. This means after the initial seed leaves (cotyledons), the plant grows one set of “true” leaves that resemble tiny versions of the adult plant’s leaves. At this point (often 7–14 days old, depending on the seed and growing conditions), the microgreens are 5–10 cm tall and have maximum flavor and nutrition.

For example, radish might be ready in 8–10 days, broccoli around 10 days, pea shoots 12–15 days, and so on. You’ll learn each variety’s timeline. It’s wise to do succession planting: start a new batch every few days so you have a continuous supply ready for harvest each week.

Use clean scissors or a sharp knife to cut the microgreens just above the soil/medium surface. It’s usually easiest to hold a bunch together gently and cut in batches. Do this carefully to avoid picking up bits of growing medium.

It’s best to harvest when the greens are dry (not immediately after watering) to prolong shelf life, and during the cooler part of the day (morning or late afternoon). Some growers will harvest to order to ensure maximum freshness.

Immediately after cutting, keep the microgreens cool. In warm ambient temperatures, they can wilt fast. Many farmers move harvested microgreens into a refrigerator or cooler at 2–5 °C. Ensure they aren’t packed wet, if there’s excess moisture, let them air-dry for a few minutes (but not in heat or sun).

Pack them in your selling containers and store refrigerated until delivery or sale. Under refrigeration, microgreens might last 5–7 days in good condition, but the sooner used, the better the taste and crunch.

This process from seeding to harvest can be repeated in continuous cycles. One of the beauties of microgreens farming is this rapid feedback loop. You’re planting, harvesting, and selling all in the same week or two. That also means you can refine your technique quickly: each week you’ll learn and adjust factors like seeding density, watering schedule, etc., to improve yield and quality.

“If you make a mistake this week, you can fix it next week”, as one microgreen grower noted about the fast turnaround.

To build a reputable microgreens business, focus on quality from the start. Some tips to ensure top-notch product:

Always wash your hands before handling seeds or plants. Sanitize trays between uses (a mild bleach solution or vinegar can kill pathogens). Since microgreens are eaten raw, cleanliness is vital to avoid any contamination. The good news is that microgreens have not been associated with the kind of foodborne illness outbreaks sprouts have, but only if you maintain good hygiene.

If your tap water is safe for drinking, it’s usually fine. But if you have any concerns (old plumbing, etc.), use filtered water to be safe.

Microgreens generally don’t require any pesticides or fertilizers, they grow so fast using stored seed energy that you harvest them before pests or nutrient deficiencies become an issue. This means your product is naturally organic or close to it.

Using chemicals on microgreens is not advisable (and could violate food safety rules), plus consumers prefer naturally grown. If you ever did need to use a pest control measure, ensure it’s food-safe and allowed, and never harvest before the safe re-entry interval for that substance. In practice, it’s best to avoid all such chemicals and stick to organic methods.

As you scale, keep notes of planting dates, lot numbers of seeds, etc. This helps with consistency and traceability (and is a part of good farm practices). If ever a customer had an issue, you can track which batch it came from.

By following these steps and tips, you will establish a smooth operation for your home microgreens farm. Now that you have an idea how to grow the product, let’s look at the business side. How to make money from microgreens farming and what your income potential might be.

One of the most common questions aspiring microgreen farmers ask is: “Can I actually make a good income from this on a small scale?” The answer is yes. Microgreens can be quite profitable, but your earnings will depend on your scale, efficiency, and market. Let’s break down the financial side, from startup costs to revenue.

As mentioned, initial costs can be relatively low. A basic home setup might cost anywhere from R5,000 to R15,000 depending on how much you invest in equipment. If you already have shelves or tables and a spare room, you might only need to buy trays, lights, seeds, and media.

If you choose to buy a ready-made kit or a more automated system (for example, some companies sell fully automated indoor growing cabinets), costs can be higher, but these are optional. Keep it lean when you start, you can always upgrade later from profits you make.

Your ongoing costs will include seeds, growing medium, water, electricity (for lights or fans), and packaging. Seeds are usually the largest variable cost. To give an idea: 1 kg of broccoli seed might produce 8–10 kg of microgreens (rough estimate; each gram of seed can yield multiple grams of greens).

Seed prices vary by variety. Peas and sunflowers are cheaper per kilo than exotic herbs, for example. As a small grower, you might spend a few hundred rand per month on seeds initially and more as you scale. Growing medium like coco coir can be bought in bricks and expanded; it’s not very expensive (and sometimes you can compost and reuse it for garden plants after microgreens have been harvested, though generally one-use for microgreens to avoid disease carryover).

Electricity usage for a typical shelf with a few LED lights is modest, perhaps on the order of tens of rands a month, but keep an eye on usage if you have many lights or climate control devices. Water use is minimal, for example, one microgreen farm reported using about 50 liters of water per week to produce 8 kg of microgreens.

That’s only 200 L a month, negligible in cost terms (but do try to recycle water when possible; one can catch drainage water and use it for garden plants, etc.). Packaging (plastic punnets or bags) will also be a regular cost; buying in bulk will save money there.

If you’re doing this alone or with family, you might not “pay” yourself a salary initially, but do note the time required. Many small microgreen operations take a few hours of work spread across the week, watering, seeding, harvesting, cleaning. It’s quite manageable, but as you grow, labor can become a factor. Some growers hire a part-time helper when supplying dozens of clients.

Don’t forget transportation (fuel for deliveries), market fees if you sell at a farmers’ market, and any business overhead (like a scale license if needed for weighing produce, or banking fees for a business account). These are usually minor but should be accounted for in your pricing.

Avoid common beginner mistakes and start your microgreens journey with clarity and confidence.

Income from microgreens depends on how much you produce and what price you sell at. Let’s consider a small-scale scenario and a larger scenario:

Suppose you start with a rack of 4 shelves, each shelf fitting 4 standard trays. That’s 16 trays in production. If each tray yields about 200 g of microgreens (this can vary widely by crop: some yield 100 g, some 300 g, etc., but 200 g is a fair average for a 25×50 cm tray), then one harvest from all your trays is roughly 3.2 kg of microgreens.

If you stagger plantings, you could harvest that much per week. Now, selling 3.2 kg in 40 g punnets means 80 punnets. At, say, R40 per 40 g wholesale to local shops or chefs (mid-range price), that’s R40 × 80 = R3,200 per week in revenue.

Monthly, this would be around R12,800. Even after costs, a good portion of that is profit. This is a hypothetical average, some farmers might do half this volume from a similar setup if they focus on lower-yield but high-value varieties, or they might sell at higher retail prices directly to consumers and make more. But it illustrates the potential.

The Mpumalanga couple (Bumblebee Organics) we discussed were doing ~30 kg a month using half their small greenhouse shelves. At an estimated wholesale price of ~R250 – R300 per kg (since they were selling to restaurants and a few stores, likely in bulk), that could be around R7,500 – R9,000 per month gross.

Once they expand to 60 kg (full capacity), it doubles. Another example: Urban Microgreens in Johannesburg, with 2,000 punnets (let’s assume 30 g each) a week, is producing ~60 kg weekly. If those are sold wholesale at, say, R20 per 30 g punnet (just guessing, as wholesale to 300+ clients likely gives volume deals), that’s R40,000+ a week! (This is a much larger operation, obviously).

The point is, as you build clientele, you can indeed reach a healthy income. Even a small microgreen business can potentially bring in a few thousand-rand profit per month as supplemental income, and a dedicated full-time effort in a metro area could scale to a comfortable living.

It’s also worth mentioning that microgreens can offer profit margins that are attractive. Many estimate margins of 40–60% after production costs, because the inputs are relatively cheap compared to the selling price. Your biggest “cost” might actually be the time and effort of marketing and distribution.

One Reddit user in South Africa shared that a family member made a good living with a diversified small farm that included microgreens, selling to local markets, restaurants, and even supermarkets like Spar. This underscores that the money is there if you can tap into diverse outlets. Another experienced grower advised that you can’t compete on price with big farms, so instead target higher-end consumers and add value – for example, offer mixed microgreen salad packs, or live trays to restaurants that want to cut fresh, or a subscription service to deliver a variety of microgreens weekly to health enthusiasts. By focusing on quality and niche markets, small producers can command prices that make the business profitable.

To maximize income from your microgreens farming, consider these tips:

Whenever possible, sell directly to the end user (consumers at a market, or via a delivery subscription). Cutting out the middleman means you can charge retail prices and keep the margin. For instance, selling a punnet for R50 at a farmers market vs. R35 wholesale to a store. Of course, this requires more effort in marketing and time spent selling.

Build relationships with chefs. They value reliability and quality, if you become their go-to microgreen supplier, you can have steady weekly orders. Often restaurants prefer a standing order like “2 kg mixed microgreens every Monday” which gives you predictable income. Fine dining restaurants, in particular, pay well for unique microgreens. You might start by giving out some free samples to local chefs to try, then converting them to customers.

It sounds obvious, but pay attention to which varieties are in demand. If radish and pea shoots are flying off the shelf but your kohlrabi microgreens aren’t as popular, allocate more trays to radish and pea. However, also watch market saturation: if every competitor sells radish, maybe you gain a niche by offering purple radish or a special mix. Stay adaptable. Also, adjust to seasons, demand can dip in winter as fewer salads are eaten. You might grow a bit less in cold months or focus on varieties like pea and sunflower that people might use in warm dishes too.

Try to grow to order as much as you can. In the beginning, you’ll guess, but soon you’ll have patterns. Microgreens that aren’t sold can potentially be juiced or pureed into pestos to sell (if you have the appropriate kitchen setup and permits for processed foods) – or simply composted. But the goal is to sell almost all you grow. If you consistently have excess, scale back sowing or find new customers. Unsold microgreens = lost revenue and wasted cost.

Consider any value-add that makes sense. Some examples: offering live trays to restaurants or caterers (they cut as needed, which extends shelf life – some chefs love this); creating mixed packs (a “micro salad mix” combining 3-4 varieties, which can be convenient for consumers); or even dehydrating and grinding microgreens into powders for smoothies (this is niche, but health stores may like it). These can sometimes allow higher pricing or access to different markets.

In summary, the income from microgreens farming can range from modest side-income to a solid full-time business. It largely hinges on how well you can grow a quality product and build your customer base. Keep your costs in check, price your products smartly (don’t undervalue, remember the premium nature of microgreens), and continually seek out new sales channels. With dedication, even a home-based operation can possibly reach profits in the range of several thousand rand per month or more.

Growing microgreens is half the battle, now you need to sell them! Fortunately, there are multiple avenues to market your microgreens in South Africa. Your marketing strategy should focus on the freshness, quality, and uniqueness of your product, and target those willing to pay for it. Here are some key channels and tips:

These are often the launchpad for small growers. Setting up a stall at a weekend farmers market in your area can connect you directly with health-conscious consumers. It’s a great way to educate people (“What are microgreens? Try a sample!”) and build a local following.

Ensure your display is attractive: bright trays or baskets of microgreens, signs listing their benefits (“40% more nutrients than regular veggies!”). Offering recipe ideas or partnering with someone selling salads or sandwiches at the market can also draw interest (“topping courtesy of [Your Farm Name] microgreens”). Markets also give you feedback on pricing and which varieties people prefer.

As noted, upscale and trendy restaurants are big buyers of microgreens. Compile a list of such eateries in your region, think farm-to-table restaurants, vegan/vegetarian cafés, juice bars, hotels, catering companies, and even chef schools.

Approach them professionally: set up a meeting or drop off a sample kit with a few different microgreens for the chef to try. Emphasize that you’re local (chefs love local sourcing), can deliver fresh regularly, and can grow to their specifications.

For example, if a sushi restaurant loves daikon radish microgreens as garnish, you could become their dedicated supplier for that. It helps to start with smaller independent restaurants which have more flexible procurement than big chains. Once you have a few chef clients and they’re happy, word-of-mouth can spread in the chef community. Consistency is key, chefs will stick with you if you consistently show up on time with quality produce each week.

Approach local independent grocers, health food stores, and organic shops. Many of these stores consignment-sell produce from local farmers or buy wholesale to resell. If you can package your microgreens attractively (with a label, logo, maybe a see-through punnet), you might get shelf space in the produce section or refrigerated section.

National supermarket chains (like Pick n Pay, Woolworths, Checkers) often have centralized procurement which is harder to penetrate initially, though some have programs for local small suppliers, but you will need to meet food safety standards and volume demands.

It might be a later goal once you scale. A more immediate target could be smaller chain stores or local branches that have some autonomy. Also consider online grocers or farm box schemes that operate in your area; microgreens are a great addition to weekly vegetable boxes.

You can market directly to consumers via social media and possibly offer delivery subscriptions. For instance, you could set up an Instagram or Facebook page showcasing mouthwatering photos of your microgreens and dishes made with them.

Post content about the benefits, behind-the-scenes of growing (people appreciate the story of who grows their food). You could take orders online and deliver to customers weekly, perhaps a “microgreen mix pack” delivered to their door.

Services like this might start small (you delivering in your car within a 10 km radius, for example), but they can build a loyal customer base. Online presence also helps your credibility when approaching other buyers, they can see you’re an active, legitimate business.

Partner with nutritionists, dieticians or cooking class instructors. Some dieticians in South Africa buy microgreen growing kits for their clients, that shows the interest in microgreens for health.

You might not be selling kits, but you can still network in those circles to encourage microgreens consumption (which ultimately benefits your sales). Maybe a local health coach wants to include your microgreens in a 7-day detox program, or a gym cafe wants to top smoothies with them. Be creative in finding opportunities.

Since microgreens are a relatively new product, brand yourself. It could be as simple as a catchy farm name and a nice label on your punnets. Share your story: for example, “Grown with love in my Johannesburg backyard” or “Urban farm producing pesticide-free microgreens.”

Customers appreciate knowing it’s a small local business. Highlight what makes you unique, are your microgreens organic? Are they grown using solar power? Do you donate a portion to community gardens? Any such angle can help create a connection with buyers.

Do some market research on prices in your area. As mentioned, typical retail might be around R30–R50 for a small punnet (30–50 g). You might price on the higher end if yours are certified organic or superior quality or mixed variety.

For restaurants, pricing may be per kg or per bulk bag, often equivalent to wholesale rates of R600–R800 per kg depending on variety. Be sure your pricing covers your costs and pays you for your time.

Don’t undervalue your product, remember, microgreens are a premium product and your target customers are those willing to pay for that quality. It’s usually better to justify a premium price with great service and quality than to try to be the cheapest in the market (a race to the bottom that small farms can’t win against big hydroponic factories).

We keep coming back to this because it’s important. Educate your customers on how to use microgreens. Provide a little flyer or recipe with ideas (“Sprinkle these radish microgreens on your next taco for a spicy crunch!”).

Explain that they should be used fresh, not cooked to death (some people make the mistake of throwing microgreens into long cooking, which kills their appeal). By helping customers get the best experience, you ensure they come back for more.

You might also clarify the difference from sprouts to alleviate any safety worries, microgreens are grown clean and have had no recorded harmful outbreaks, unlike sprouts. So they are safe when handled properly.

Finally, be persistent and patient in marketing. Early on, you may knock on a lot of doors and give out samples. You might have a slow market day or a chef who stops ordering unexpectedly (maybe a menu change). That’s normal in any business.

Keep pushing and find new leads. South Africa’s microgreens trend is still in a growth phase, as one article noted, with microgreens becoming more than a passing foodie trend and increasingly “readily available” as demand grows. By establishing your presence now, you’ll ride that wave as more people incorporate microgreens into their diets.

When starting any food-related business in South Africa, even a small home-based one, it’s important to understand the legal and regulatory considerations. Microgreens farming may be small-scale agriculture, but once you start selling food to the public, you have to comply with certain food safety and business regulations. Here’s what you need to know and do to operate legally and safely:

If you are just testing the waters, you can operate as a sole proprietor under your own name. However, it’s often wise to formally register a business (for example, as a private company or keep it as sole prop but with a trading name).

This isn’t strictly required to start selling at small scale, but having a registered business and a business bank account lends credibility and will be necessary if you expand (especially to deal with bigger clients or formal supply contracts).

If you use a trading name (say “GreenLeaf Micro Farm” instead of just your name), you should register that as a business or a trade name with the local authorities. Registering with the Companies and Intellectual Property Commission (CIPC) is straightforward if you go the company route. Also, if your turnover exceeds certain thresholds, you’d have to register for VAT, etc., but that’s usually when you’re much larger.

South Africa’s regulations require that any place where food is handled for sale must have a Certificate of Acceptability (CoA) issued by the local municipality’s health department. This is mandated by Regulation R638 of the Health Act (which replaced the older Reg. 962).

This certificate basically is an inspection that ensures your kitchen or processing area meets hygiene standards, clean surfaces, proper sanitation, pest control, etc. Yes, this applies even to a home kitchen if you’re using it to package microgreens for sale.

The process: you contact your municipality’s environmental health office, apply (often free or minimal cost) for a CoA inspection, and an officer comes to inspect your premises. They’ll check things like: do you have washable surfaces, a fridge at correct temperature, a hand-wash basin, etc.

If you meet the requirements, you get the certificate (which you should display in your area of business). It might sound daunting but many home-based food businesses have CoA’s, it’s feasible. Operating without it can get you into trouble if you’re caught or if a customer complaint and triggers an inspection.

The laws (like R638 and SANS 10049) lay out a lot of hygiene rules: things like no pets in the food area, proper attire (you or staff should ideally use hairnets, etc., when packing produce), avoiding any cross-contamination (microgreens are typically ready-to-eat, so treat them with care as you would a salad product).

You might consider doing a basic food handler training course, some municipalities even require the person in charge to have one. Even if not, it’s good practice to learn about food safety (covering topics like how to sanitize, how to avoid bacterial growth, etc.).

Keep records, e.g., cleaning schedules, temperature logs for your fridge, as this is encouraged by hygiene regulations and will be critical if you pursue certifications.

If you package your microgreens for retail, you should adhere to food labeling regulations. In South Africa, processed food labels have strict rules, but for fresh produce in punnets, the requirements are simpler (often just product name, weight, producer contact, and packing date/batch).

Make sure you do not make any unverified health claims on labels; stick to general terms like “nutritious” rather than “cures diseases” unless you have approval for such claims.

Also, indicate if your product is grown organically (and be truthful, if you’re not formally certified organic, you can say “naturally grown, no pesticides” but do not use the term “Certified Organic” unless you are).

Accurate labeling is not only law but builds trust, include that it’s microgreens, the variety if single (or say “Assorted Microgreens”), and net weight (in grams).

Avoid common beginner mistakes and start your microgreens journey with clarity and confidence.

Beyond the CoA, check local by-laws if any regarding home businesses. Most residential areas allow small home enterprises as long as there’s no nuisance (excess traffic, noise, etc.).

Selling at markets might require a permit from the market organizers. If you deliver food, no specific additional license is needed, but ensure your vehicle is clean.

Down the line, if you scale, you might need to comply with more advanced food safety standards (HACCP, etc.) especially if you want to supply big retailers, for instance, Shoprite’s supplier criteria explicitly require a CoA and also adherence to food safety audits and relevant Acts. But at the entry level, focus on the CoA and basic hygiene.

The microgreens industry is still new, and as an M&G article noted, it’s “not yet properly regulated” in terms of a definition, e.g., some unscrupulous folks were selling older baby greens as “microgreens” to add weight.

While there’s no microgreens-specific law against that, it’s essentially misleading the customer. Ethically, you should stick to true microgreens (harvest at the right stage) and uphold quality.

Customer feedback will quickly tell you if your quality slips. Being self-regulated in this way will keep the overall standard high. Eventually, we may see industry guidelines, but as of now, your reputation is your quality guarantee.

Consider getting product liability insurance once you start selling to the public. It’s not a legal requirement, but it’s a safety net in case someone claimed they got sick (even if it might not be your fault, you want coverage).

Also, if you supply stores or restaurants, some might ask if you have liability cover. Shop around with insurance brokers for a small food business policy.

Even small businesses should keep financial records. If you are making an income, you are supposed to declare it in your tax return. The benefit of recording expenses is you can deduct those business expenses as well.

This is more business 101, but worth noting: set aside money for income tax if applicable, and if you eventually register for VAT (if you go over the threshold, currently R1 million annual turnover), you’ll need systematic invoicing. Again, that’s further down the road for most.

Overall, due diligence in legal compliance will not only keep you out of trouble but also enhance your business’s credibility. Clients, especially corporate ones, feel more confident buying from a producer who clearly follows health regulations and can show a Certificate of Acceptability and other credentials.

It may take a bit of paperwork and preparation to get these in place, but it is well worth it. Food safety is paramount: always remember that people are consuming your microgreens raw, so you must ensure they are grown and handled in a safe, clean manner from seed to sale.

To wrap up, here are some final tips and best practices to help you thrive in your microgreens farming venture:

It’s tempting to go big quickly, but it’s often wiser to start with a manageable number of trays and a few varieties. Hone your growing technique and gauge local demand. As you secure more customers, you can reinvest profits to expand capacity. This stepwise growth minimizes risk and lets you learn as you go without overwhelming yourself.

Connect with the microgreens and small farming community. Join online groups or forums (there are South African farming forums and Facebook groups for microgreen growers). You’ll pick up invaluable advice and possibly leads on buyers.

Sometimes growers even collaborate, for example, if one gets a large order they can’t fulfill alone, they might subcontract to another. Sharing knowledge about things like where to source the cheapest seeds or packaging can improve your business.

Keep an eye on food trends. Maybe a certain microgreen variety becomes the next big thing (for instance, red amaranth might catch chefs’ attention for its color). Be ready to experiment.

Also, consider diversifying a bit, some microgreen farmers add other quick crops like baby greens, wheatgrass shoots, or herbs to their catalogue. As long as it fits the model of fast, small-scale crops, it could complement your offerings. But don’t spread yourself too thin; core microgreens often provide plenty of variety by themselves.

Whether it’s a chef or a market shopper, build a relationship. Personal connection is one advantage you have as a small business. Reliability and good communication go a long way. For instance, if you have a bad batch and can’t deliver on time, let the client know early and maybe bring them a complementary extra of something else.

These gestures keep clients loyal. Many chefs will stick with a slightly more expensive local microgreen supplier because of trust and quality, rather than switch to a cheaper unknown source.

As you grow, consider writing down your standard operating procedures. It sounds formal, but even notes like how you sanitize, how you pack, etc., help maintain consistency especially if you hire help. Plus, documented processes are necessary if you ever pursue formal food safety certifications.

At the end of the day, microgreens are about flavor punches. Strive to grow them in a way that maximizes taste, usually that means not letting them grow too old (beyond microgreen stage) and keeping them stress-free so they’re tender.

Some growers experiment with slight things like changing light spectrums or adding natural nutrients to water to enhance flavor, but the consensus is good seed and fresh harvest = best flavor.

If your microgreens consistently taste great, you’ll stand out, since flavor is what chefs are after (the “flavour intensity” is why microgreens have moved from garnish to center-stage in cooking).

Agriculture is always a learning process. Attend workshops or short courses if available (some local agricultural colleges or private institutes might have urban farming or hydroponics courses that include microgreens).

Read up on latest research, for example, scientists are always comparing nutrient levels, or testing new varieties. Knowing, say, that microgreens grown in slightly colder temps have better color, or that a certain variety has exceptionally high antioxidants, can be a marketing or production advantage.

Microgreens farming can be quite fun and rewarding. Watching seeds sprout and turn into a lush mini “forest” of greens in a matter of days is almost magical. Enjoy the process of nurturing these little plants.

Your enthusiasm will show in the product and how you sell it. Many people find it therapeutic to farm on a small scale, and that passion can translate to business success.

By following the guidance in this article, leveraging the opportunities, mitigating the challenges, growing with care, and selling smartly, you’ll be well on your way to building a profitable microgreens farming business in South Africa. From a home kitchen counter or a backyard greenhouse, you can cultivate not just nutrient-rich greens, but also a thriving enterprise.

In conclusion, microgreens farming in South Africa offers a promising path for aspiring small-scale farmers and home entrepreneurs. It combines the best of modern urban agriculture, high yield in small spaces, quick returns, and alignment with healthy living trends, with the fulfillment of producing food that is both nutritious and gourmet.

South African microgreen pioneers have already proven that this “tiny crop” can deliver truly big returns, both financially and in community impact.

As the market expands and more consumers discover these flavorful mini-greens, there’s ample room for new growers to enter the field. By focusing on quality, ensuring food safety, and tapping into the local demand from restaurants and health-conscious shoppers, you can carve out your own niche in the microgreens sector.

Remember to incorporate the keyword of success: adaptability. Whether it’s adjusting to seasonal demand, adopting new varieties, or navigating regulatory steps, the most successful microgreen ventures will be those that stay flexible and customer-focused.

The legal requirements like obtaining a Certificate of Acceptability and maintaining hygienic practices might seem like extra chores, but they ultimately build a stronger foundation for your business, giving you access to larger markets and the confidence of your clients.

Similarly, the challenges like consumer awareness are actually opportunities in disguise: each conversation about what microgreens are is a chance to win a new loyal customer with a great story and product.

In the coming years, we can expect microgreens to become even more mainstream in South Africa, appearing in more households and restaurant menus, given their “abundance of flavor and big health benefits in a tiny package,” and the fact that they’re far more than just a passing trend.

This growth will likely be fueled by small-scale producers and innovative startups, people like you, who bring passion and creativity to farming these miniature veggies.

So, if you’ve been dreaming of starting a microgreens farming business at home, now is an excellent time to sow those seeds (literally and figuratively). With careful research, a bit of experimentation, and the guidelines provided in this article, you can launch a venture that is personally rewarding and financially viable.

The journey might start on a kitchen counter or a spare room shelf, but it could very well grow into a significant agribusiness endeavor.

Microgreens farming in South Africa exemplifies how agriculture is evolving, it’s becoming more urban, more sustainable, and more accessible to anyone with the dedication to grow. By diving into this green venture, you’re not just cultivating tiny greens; you’re cultivating a new way of farming and a fresh chapter in your own life.

Here’s to your success in microgreens farming, may your business (and your microgreens) thrive and flourish!

Passionate about growing and empowering others! I’m a microgreens grower and business enthusiast based in South Africa, focused on helping people grow nutritious greens from home and turn small spaces into thriving businesses. Through local insights, hands-on experience, and a love for sustainability, I’m building a community of growers who want to live healthier, earn extra income, and make a positive impact, one tray at a time.